I.6.

It follows from the foregoing, that the continuous constant flow rate is not the most efficient platform for the operations that comprise the assay protocol, since mixing, separations, incubation, monitoring, etc., require different times frames for optimum performance. Therefore transporting samples trough the flow path at a constant flow rate, compromises the efficiency of an assay , as much as it as it would impair driving of a car, equipped with only one forward gear. Curiously, Flow Injection is still exclusively performed on continuous flow basis, the legacy of AutoAnalyzer .

Programed Flow Injection (pFI) introduced for the first time in this Tutorial (Chapter 1), employs different flow rates to optimize the assay protocol, with aim to enhance the analytical readout, reduce reagent consumption and waste generation.

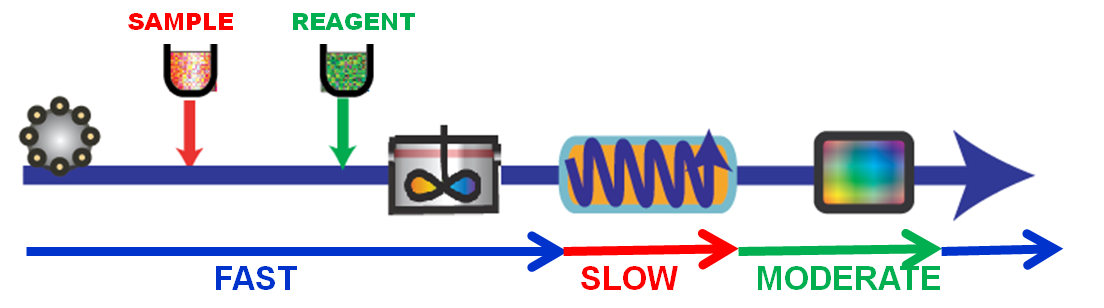

For assays based on slow chemical reactions, carried out in a traditional FI system, operated at constant flow rate, the only way to increase the incubation time ľand yield of a reaction- is to increase the length of the reaction coil. This increses dispersion of sample, decreases sampling frequency and generates an excessive volume of chemical waste.

By slowing the flow rate, when the sample is in a short reaction coil , the incubation time is increased, without increase of dispersion and the sensitivity of assay is enhanced. Similarly, separations, and UV or heat assisted sample decomposition, will also benefit from appropriate flow rate management.

Programming Flow Injection

Once you have exhausted all possibilities and failed, there will

be one solution, simple and obvious, highly visible to everyone else.

SNAFU

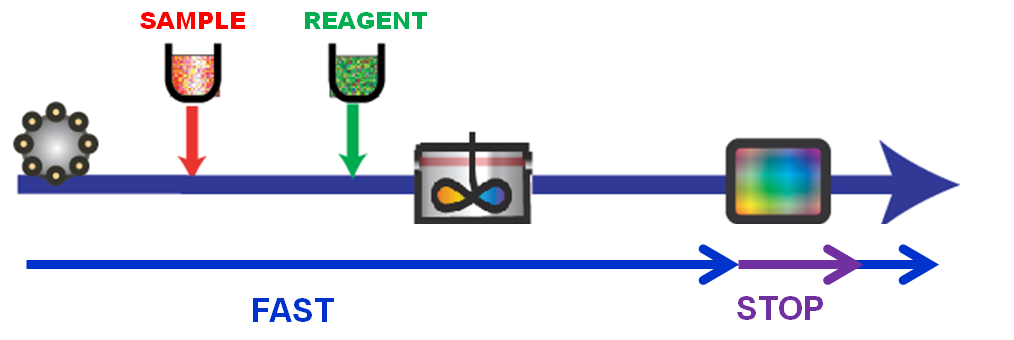

For reaction rate measurement, the flow rate is to be kept high, in order to promote mixing of sample with reagents and stopped, when the reaction mixture reaches the flow trough detector, to carry out reaction rate measurement.